by Chris Blake

Simulation of the injection and compression molding processes is often left to the end of the mold design phase, as it is typically a complicated and lengthy endeavor. If the expertise is in house, simulation specialists are often very busy tackling multiple designs in the business pipeline. If simulations are outsourced, there is an inherent delay due to knowledge transfer and the availability of consultants, not to mention the raw computational time.

Simulations are often mandated by the OEM, and so injection molders and mold makers must bite the bullet, and absorb the analysis effort into their plans. But what if simulation was accessible, affordable and fast enough that analyses could be conducted as the plastic part or as the mold is being designed? What if simulation could actually inform the design on the fly? This is the essence of Easy Mold Cooling Prediction with SimForm. And now, thanks to a tighter integration with the mold design software XMD, developed by Synergetic Engineering, simulation-driven design workflows are that much more convenient.

Co-development through partnership

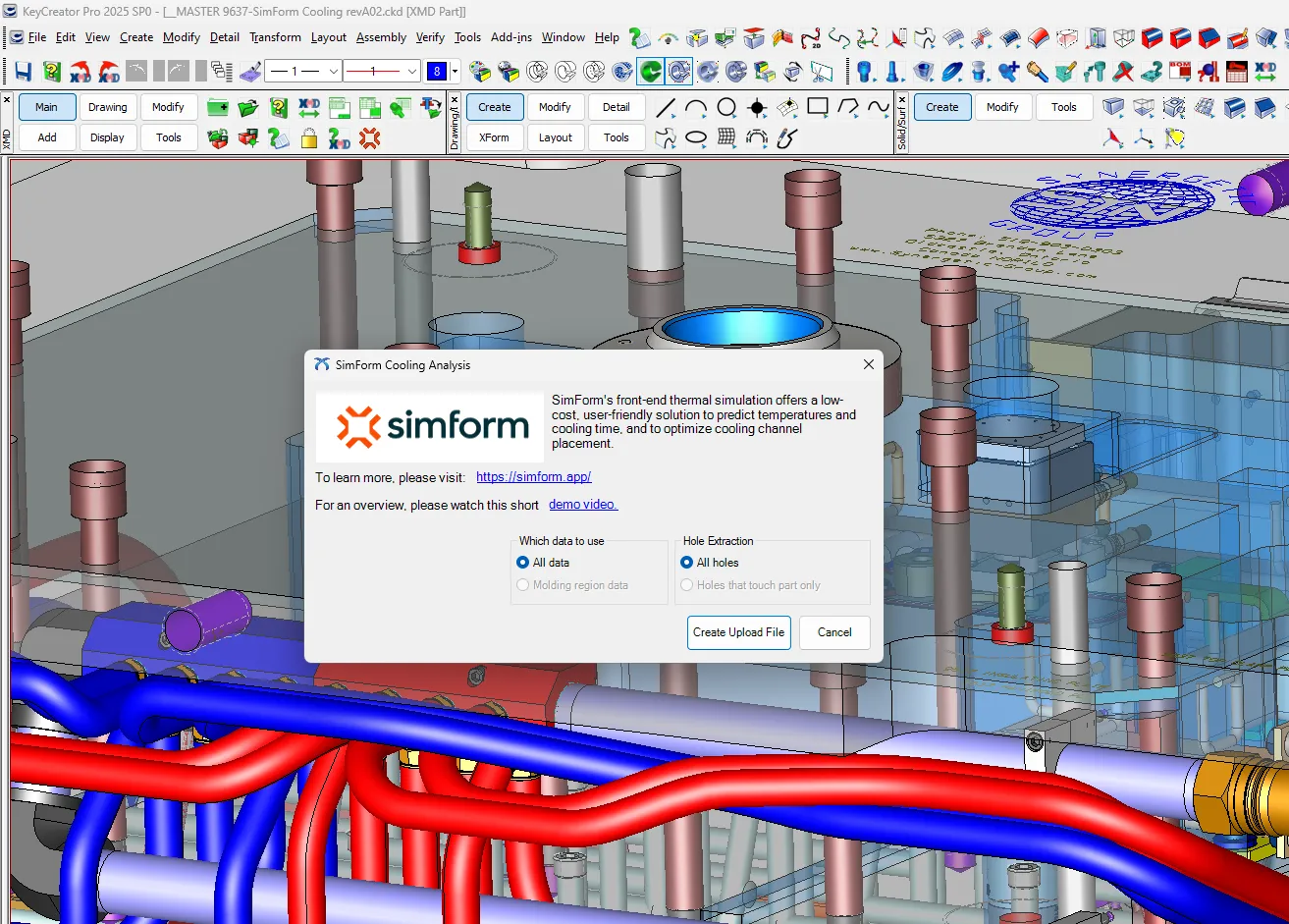

Since announcing their partnership, Maya HTT — the company behind SimForm — and Synergetic Engineering have worked jointly to develop an integration between their tools. Now, with the 2025 release of XMD, users have access to the “SimForm Cooling Analysis” button, which produces an upload file ready to be brought into the SimForm mold flow simulation software. Waterline circuits are interactively and automatically labelled for IN/OUT, and coloured for better visualization. Users can elect to export just the mold components in proximity to the plastic part, or the entire mold assembly for a more complete experience in SimForm.

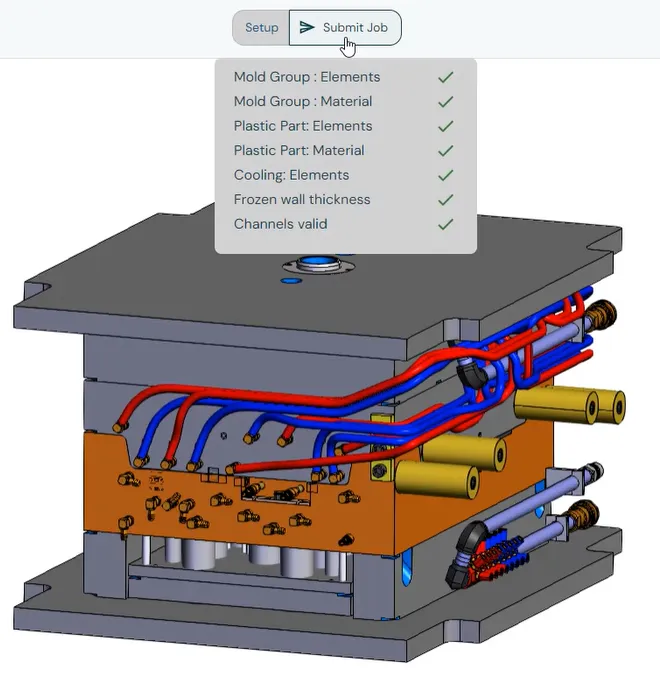

The upload file contains all relevant geometric data as well as the complete definition of the SimForm job. That means that once ingested into SimForm, the user need do nothing else than click on Solve.

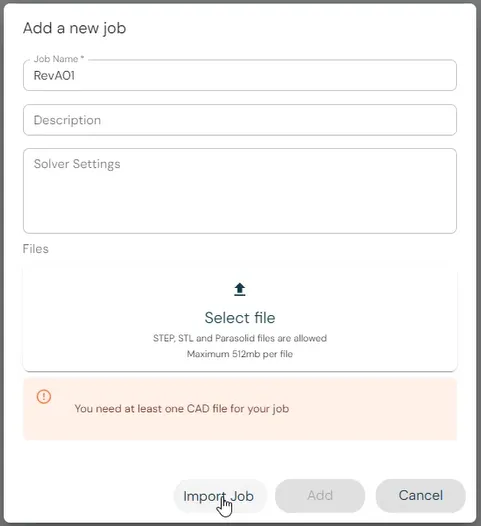

As of release 2024.12 of SimForm, the “Import Job” command is accessible when creating a new simulation job. After selecting the upload file produced by XMD, the geometric data is read, categorized and assigned the correct mold materials; the parts are assigned the correct resin; and the cooling channels, including baffles, inlets, and outlets, are fully defined. With one click, the entire SimForm job is ready to solve.

What is simulation driven design?

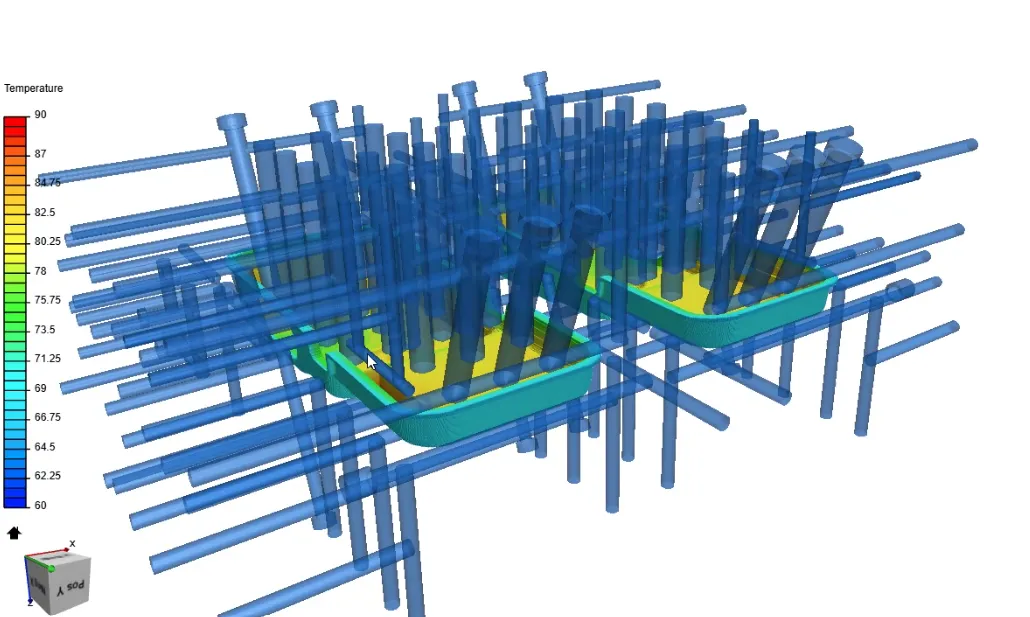

A simulation-driven design approach allows designers to quickly test out different mold cooling concepts, like rerouting channels, adding baffles, introducing a copper alloy insert, or analyzing the cost-benefit of 3D-printed conformal cooling channels. According to a study by research firm Aberdeen, the increasing pace of innovation and pressure to meet faster delivery deadlines are the main drivers of the move towards a simulation-driven design process. The study also found that best-in-class companies are 56% more likely to invest in simulation than all others.

To know more about conformal cooling channels and especially the return on investment, please visit our ROI Calculator.

Access to thermal simulation earlier in the process means the mold designer can quickly and easily understand the impact of the choice of actions and mechanisms on the cooling time and part quality, leading to an overall improved mold design, and a reduction in engineering cost and lead time.

It also allows for design variation testing without the overhead of manually rebuilding complex geometry. This can encourage more experimentation and greater optimization.

The integration between SimForm and XMD greatly reduces the effort needed to build an injection molding simulation model and empowers teams to leverage simulation-driven design even without advanced mold flow simulation skills.

When mold simulation software is naturally integrated into the early phases of design (rather than a checkpoint at the end), teams can catch thermal bottlenecks before they turn into costly delays. There’s a sizable competitive advantage to evaluating multiple scenarios within the same day — even within the same meeting. Fast-paced manufacturing environments demand quick, collaborative design decisions from mold makers, molders, and OEMs. Early simulations empower teams to achieve just that.

Scaling efficiency across teams

The SimForm-XMD design workflow makes it simpler to keep simulation standards consistent as organizations grow or distribute design responsibility across global teams. Because job setup and materials assignment are automated, users can avoid discrepancies in analysis caused by inconsistent modeling practices or versioning issues.

The integration also helps newer engineers or cross-functional contributors to participate meaningfully in thermal analysis tasks — even if they lack advanced injection molding simulation backgrounds. In short, democratized access to mold flow simulation breaks down silos, improves communication between mold designers and analysts, and leads to better overall outcomes.

Future considerations

As this partnership continues, the intention is to further enhance and accelerate mold design iterations, so that mold makers continue to respond to the increasing requirements and accelerated timelines from the market. Exchanging incremental changes to the design from XMD is one low hanging fruit, while returning design recommendations back from SimForm will close the collaborative loop. Both companies look forward to seeing how the relationship will elevate the opportunities for the mold design community.