What can SimForm do for you?

Design better parts

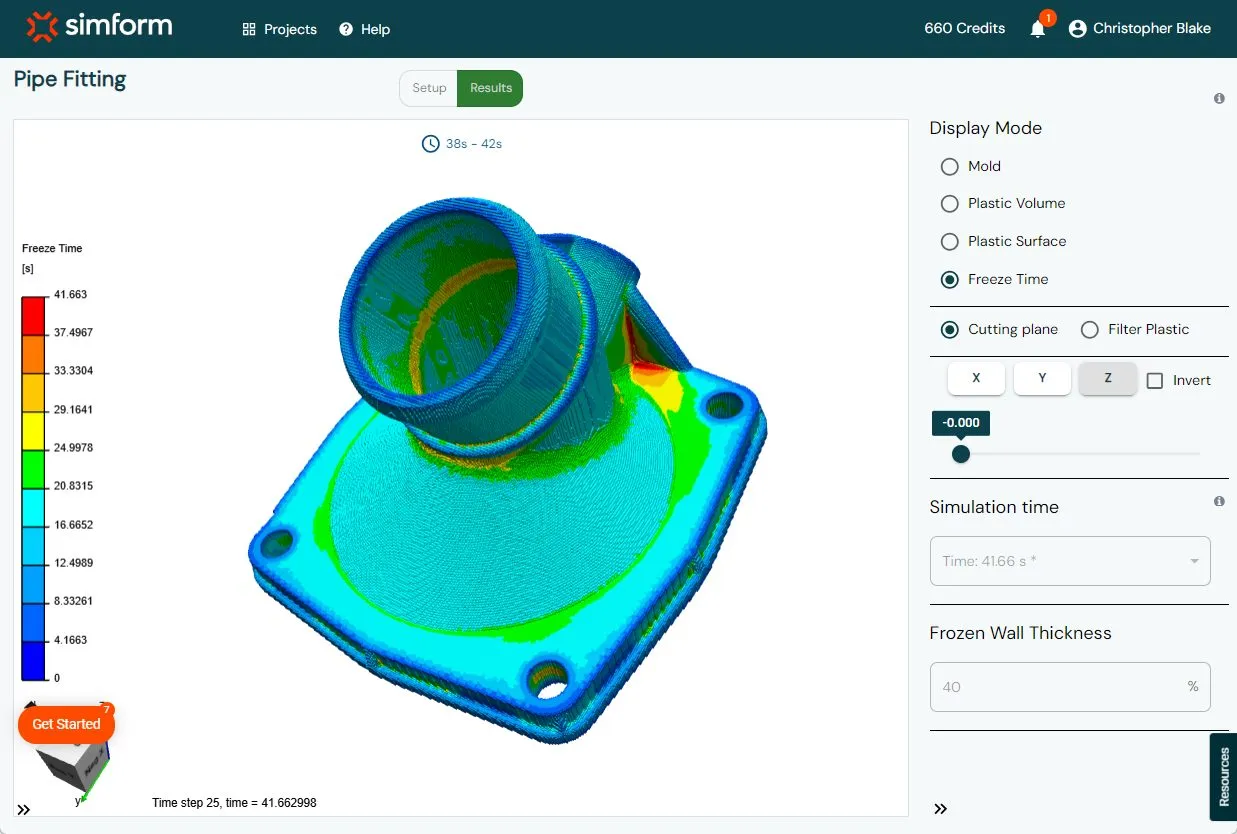

- Catch uneven cooling before production

- Reduce late-stage design changes and costs

- Improve surface quality and aesthetics

- Validate thickness & geometry choices

- Build confidence in design reviews

Produce parts faster

- Cut cooling cycle times & boost throughput

- Reduce shrinkage, warpage, & defects

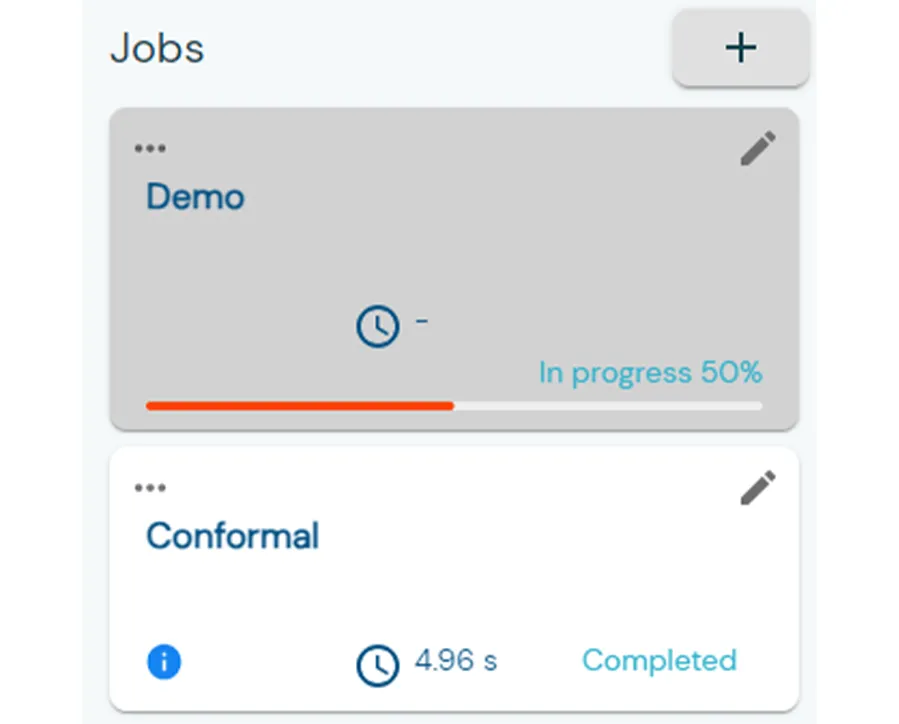

- See & compare cooling layouts with ease

- Improve consistency across production runs

- Support leaner quoting & faster delivery

Design molds faster

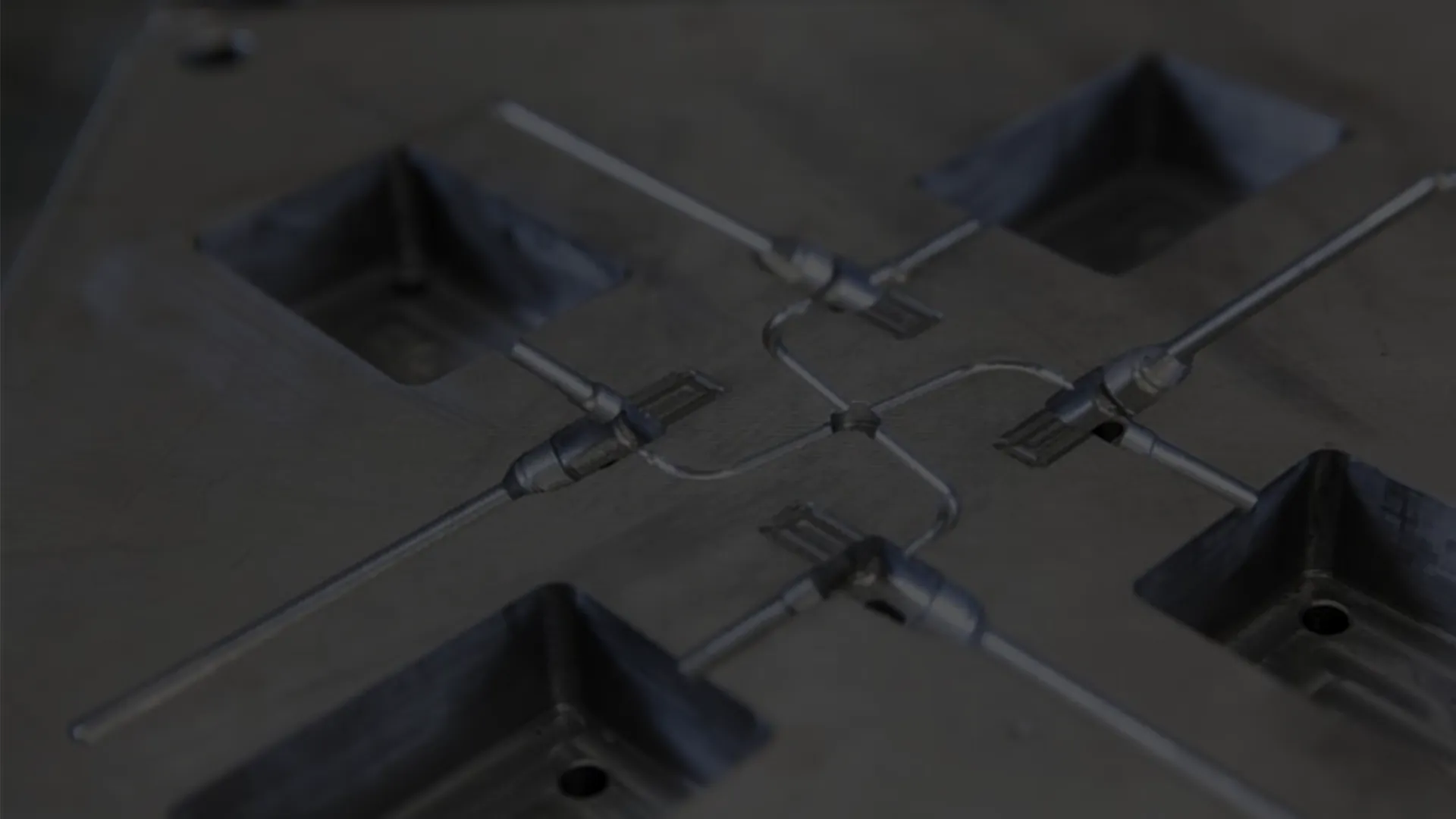

- Optimize cooling layouts with speed

- Evaluate mold materials & inserts quickly

- Predict safe ejection times reliably

- Reduce mold tryout time on the shop floor

- Deliver molds that hit cost & quality goals

Trusted by

What our clients are saying

SimForm has the potential to become a game-changer for mold cooling design optimization. It promises to be a key asset in our tool development process.

Raphaël B

Engineering Tools Manager, TIBO

SimForm allows us to quickly evaluate customer part designs to rapidly determine whether there is any thermal processing benefit to be gained. These benefits include reduced injection molding cycle times, optimized flow of plastic material inside the mold, and improved quality of the molded plastic part.

Clay Stephens

CEO & Co-Founder, Synergy Molding Technologies

Having a tool that would allow us to predict the hotspots and then adjust for those hotspots in the tool would be wonderful.

Scott Peters

Molded Marketing LLC

Cooling insights without the wait

SimForm delivers simulation results in about 15 minutes compared to hours on legacy tools.

No installs, no training, no wasted cycles and no expensive workstations.

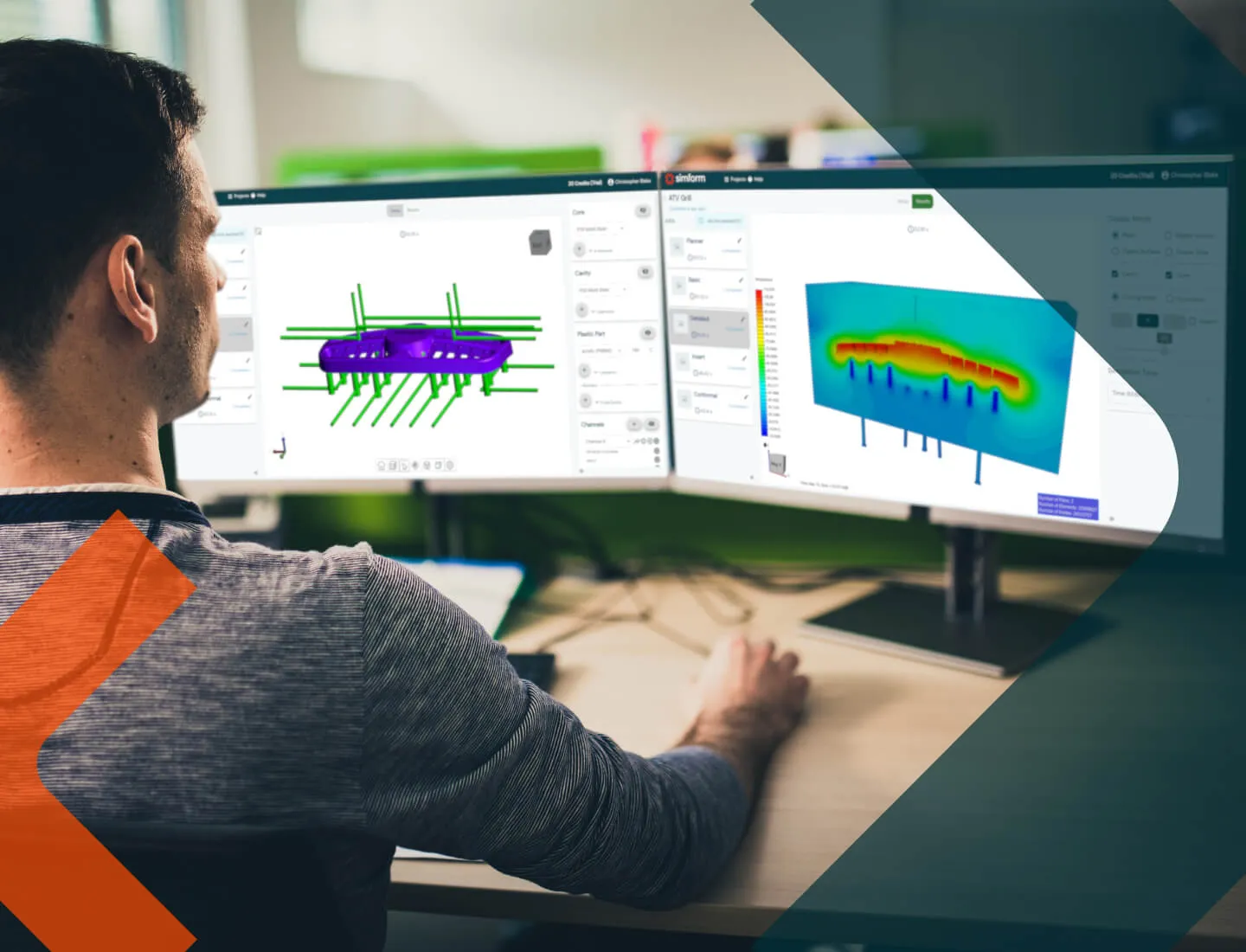

What can you do with SimForm?

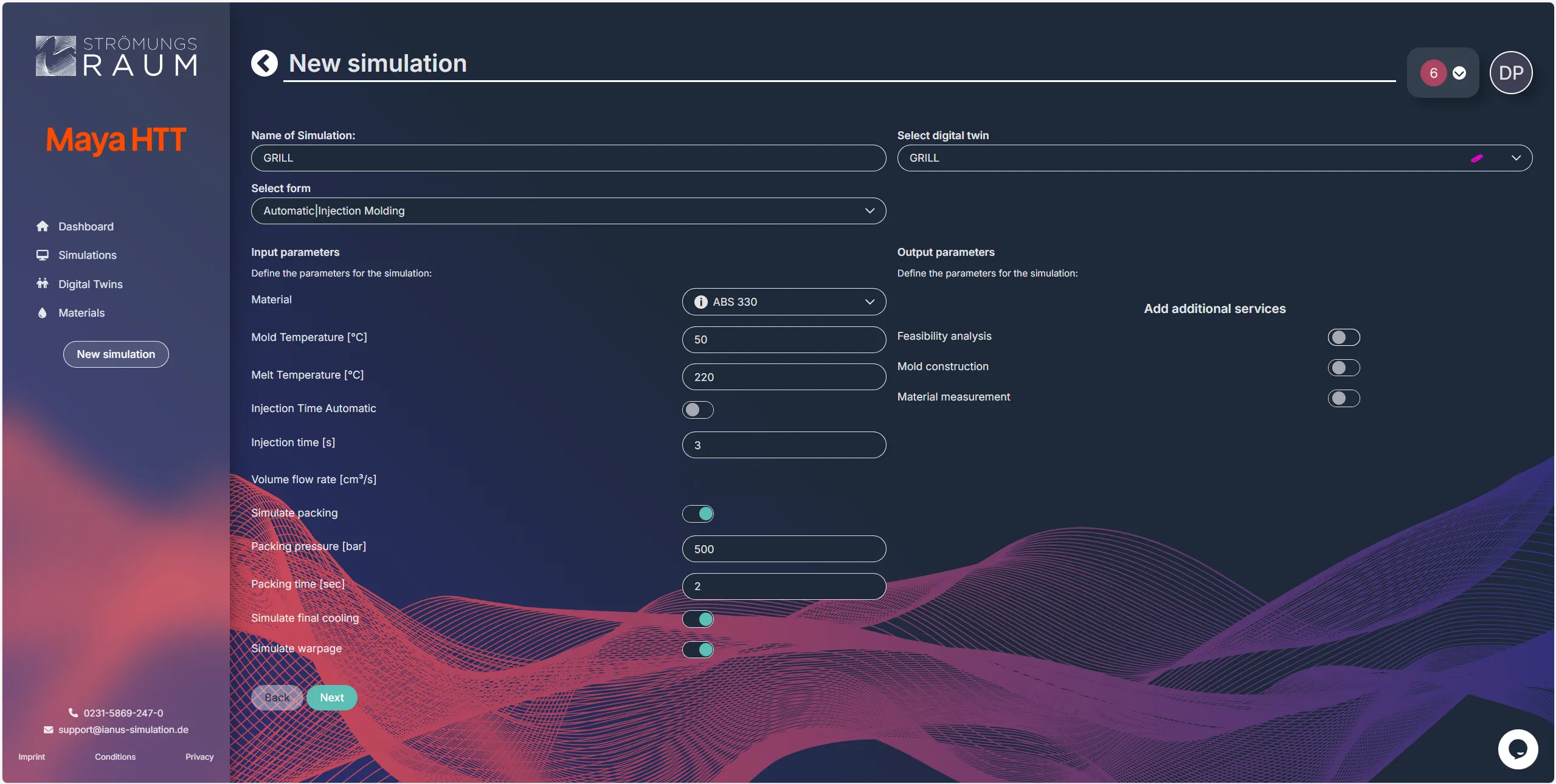

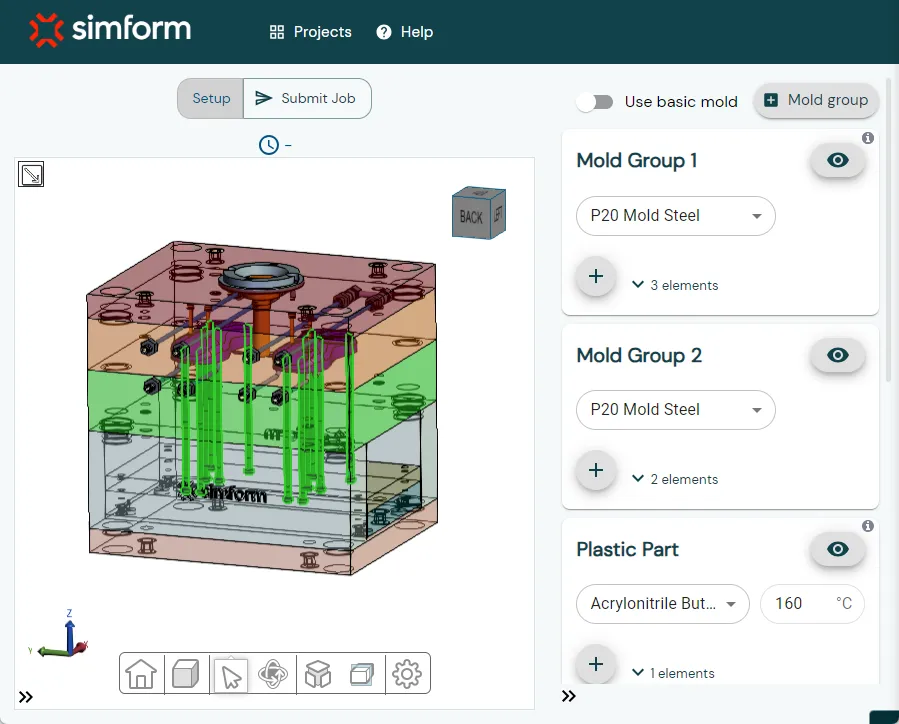

Define your mold

- Import CAD directly from STEP or Parasolid

- Select plastic, mold, & insert materials

- Tag cooling channels including conformal

- Adjust water temp & cycle parameters

- Compare design variations side by side

Crunch the numbers

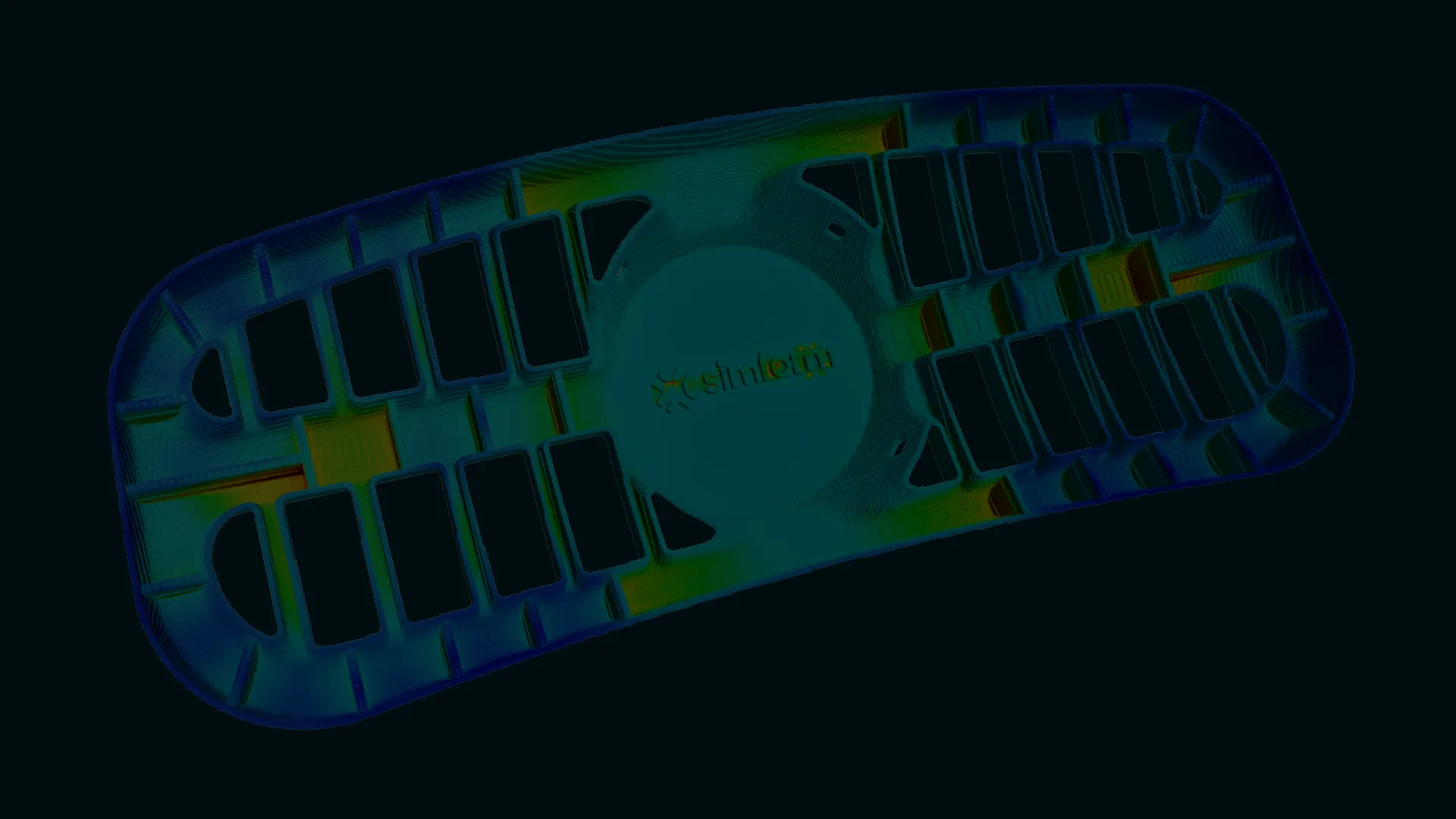

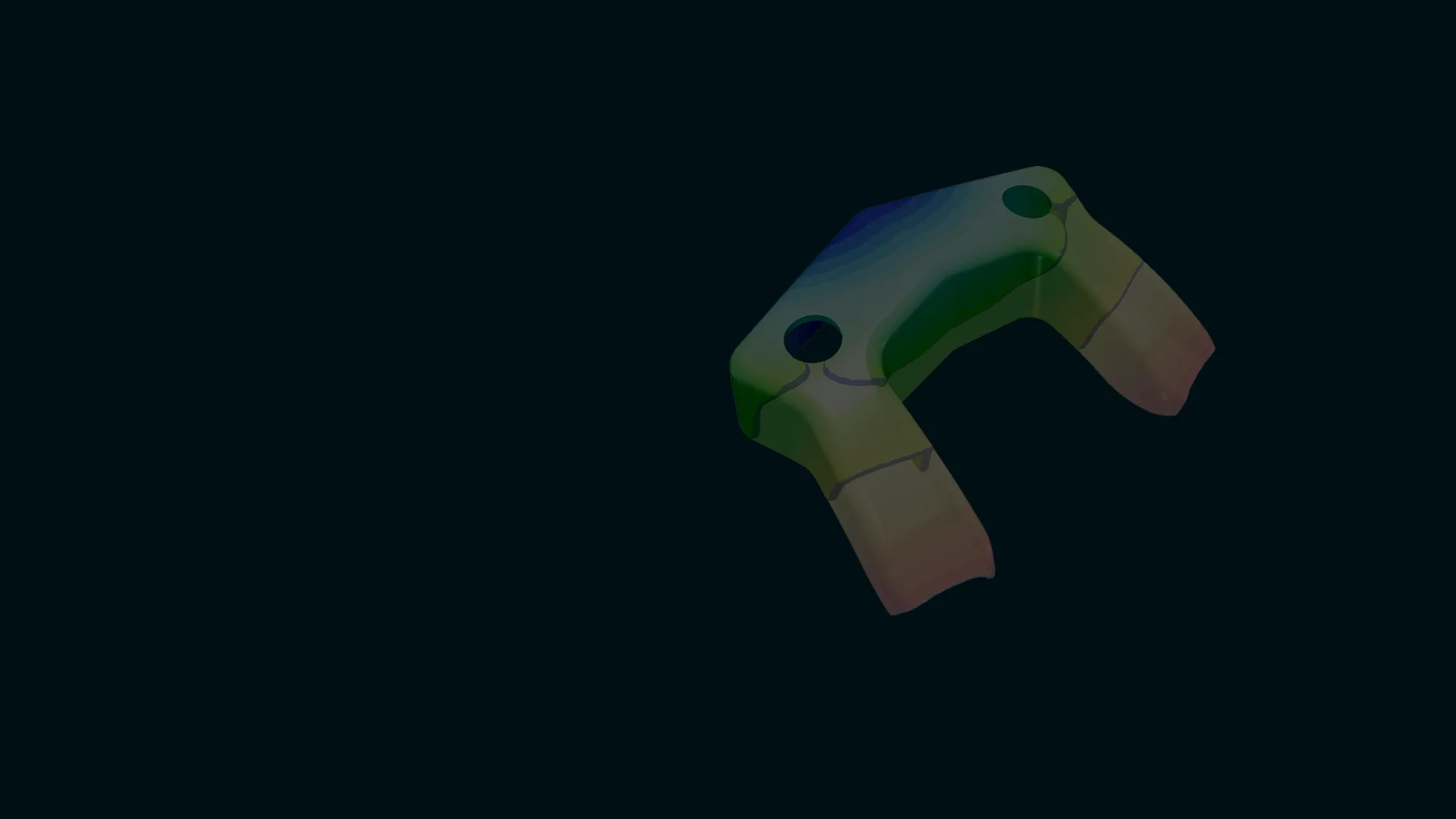

- Predict part & mold temp distributions

- Results in under 15 mins with cloud compute

- Skip meshing & prep, even on complex parts

- Run securely from any browser

- Pay only for what you use

Go further with our capabilities

- Combine cooling with fill & pack via partners

- Unlock broader part & mold insights

- Identify risks earlier in the design cycle

- Confidently justify design & tooling decisions

- Future ready for workflow connections

Latest resources

Yes, cooling matters

Without an effective cooling strategy, your injection or compression mold design runs the risk of producing plastic parts with dimensional instability, poor surface finish and long cycle times.

To achieve high-quality parts with shorter cycle times and lower costs, you must optimize your cooling design.

SimForm is the plastic molding simulation software that makes mold cooling prediction easy.

Thermal expertise meets plastic molding

Discover a powerful and reliable mold design solution built for the plastic injection and compression molding industries by the thermal-fluid simulation experts.

Maya HTT, leader in thermal-fluid simulation software development, is proud to bring more than 40 years of expertise to the mold, tool and die industry.

Experience mold cooling made easy.

Explore plastic injection and compression mold cooling design solutions.

Find out how SimForm can help you today.